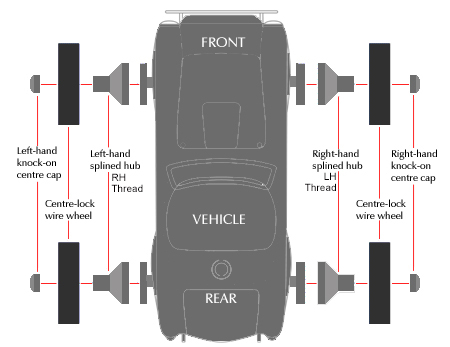

A centre-lock wire wheel is fitted onto a car axle using a splined hub; the splines (or serrations) of the hub lock with the splines on the inside of the wheel centre to produce drive. Splined hubs may be integral fitting or bolt-on. Please refer to the vehicle’s service manual for instructions on fitting integral splines. The diagram below illustrates fitting bolt-on hubs.