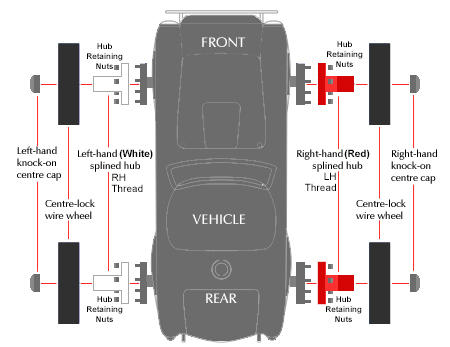

There are 4 splined hubs, 2 red and 2 white. It is very important to fit these to the correct side of the vehicle.

The RED hubs are fitted to the RIGHT-HAND side of the vehicle (as you are seated in the vehicle). The WHITE hubs are fitted to the LEFT-HAND side of the vehicle (as you are seated in the vehicle). This gives you a left hand thread on the right-hand side and a right hand thread on the left-hand side of the vehicle.

You must ensure that these hubs sit perfectly flat with the original vehicle hub face.

The hubs must be fitted to the vehicle with tapered wheel nuts (usually used to fit original steel wheels) and make sure these wheel nuts are not too long so as to prevent the wheel seating correctly. These nuts must be tightened to the original vehicle wheel nut torque specification. Once the vehicle has been driven, the wheels are to be removed and these nuts retorqued.